We are making the topic of alternative plastics more visible

new generation of PLANT-BASED plastics

THE SECRET IS IN THE CHEMICAL COMPOSITION

We harness the power of plant biomass, tapping into cellulose and lignin, to craft the foundation of our biopolymer creations.

Our breakthrough catalyst skillfully dismantles precise chemical bonds in lignin, transforming it into soluble oligomers - the essential building blocks for our innovative thermoplastic polymers.

Tailoring our approach, we blend these oligomers with cellulose and its derivatives to mold diverse, cutting-edge biocomposites.

Only 4 steps stand between the usual green waste and the product of the new generation

STEP 1

Preparation of biomass, which consists in the production of a homogenate for further chemical extraction

STEP 2

Destruction of specific chemical bonds in lignins with the formation of oligomers and subsequent polymerization

STEP 3

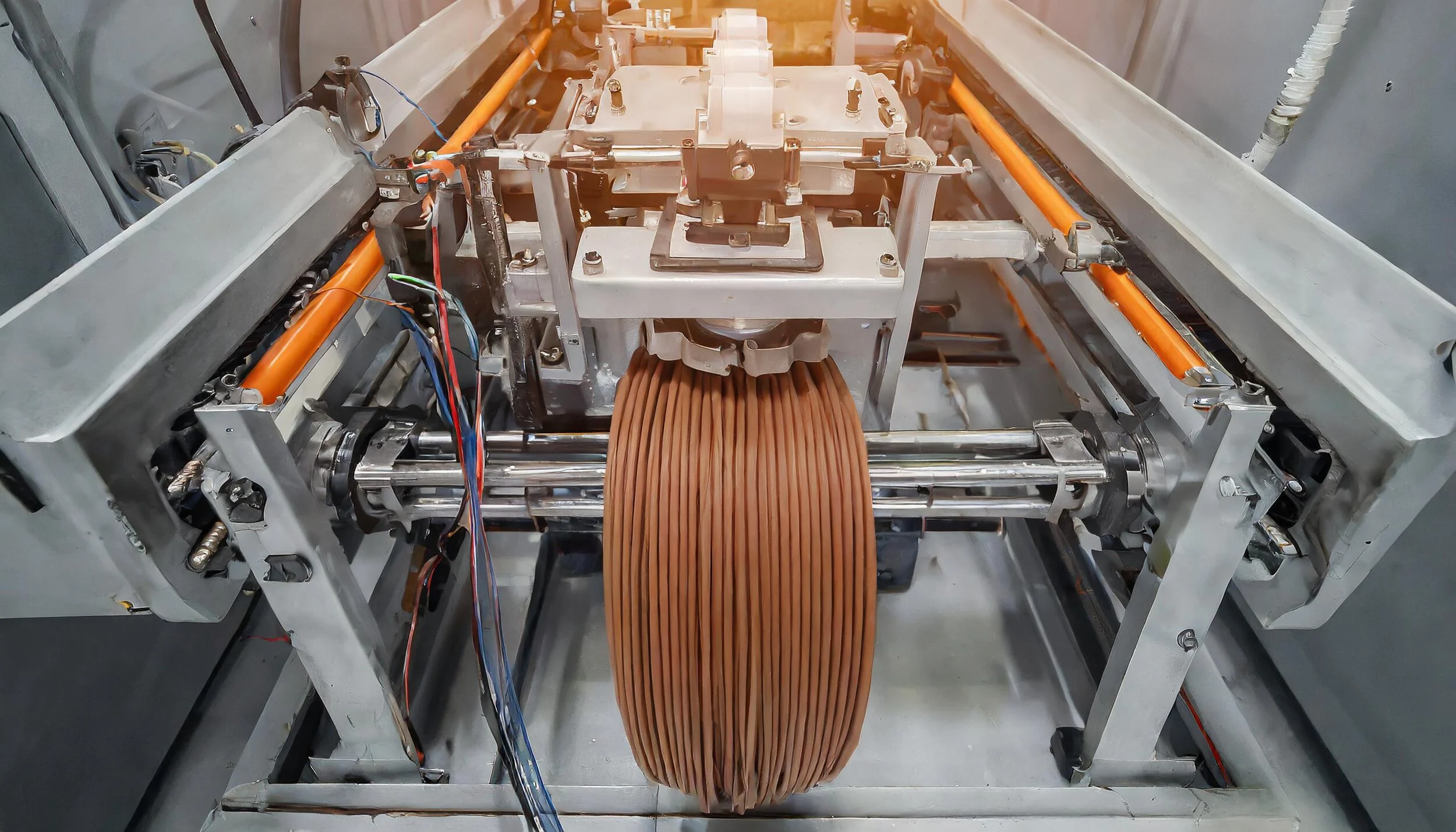

Twin extrusion, addition of fillers based on LCNF, MCNF and biopolymers followed by filamentation

STEP 4

Formation of compact granules for hot pressing or injection molding and production of finished products

Leveraging our robust intellectual property portfolio, we're pioneering a new era of advanced natural materials that transcend traditional plastics. Our commitment to utilizing waste, residues, and side streams champions the circular economy and combats pollution. Our technology stands out with compelling advantages over conventional options:

Enhanced resistance to mechanical stress and moisture

Cost-effectiveness

Superior quality

Improved performance

Energy efficiency

Water conservation

Reduction of plastic waste

Minimized land usage

Lower carbon footprint